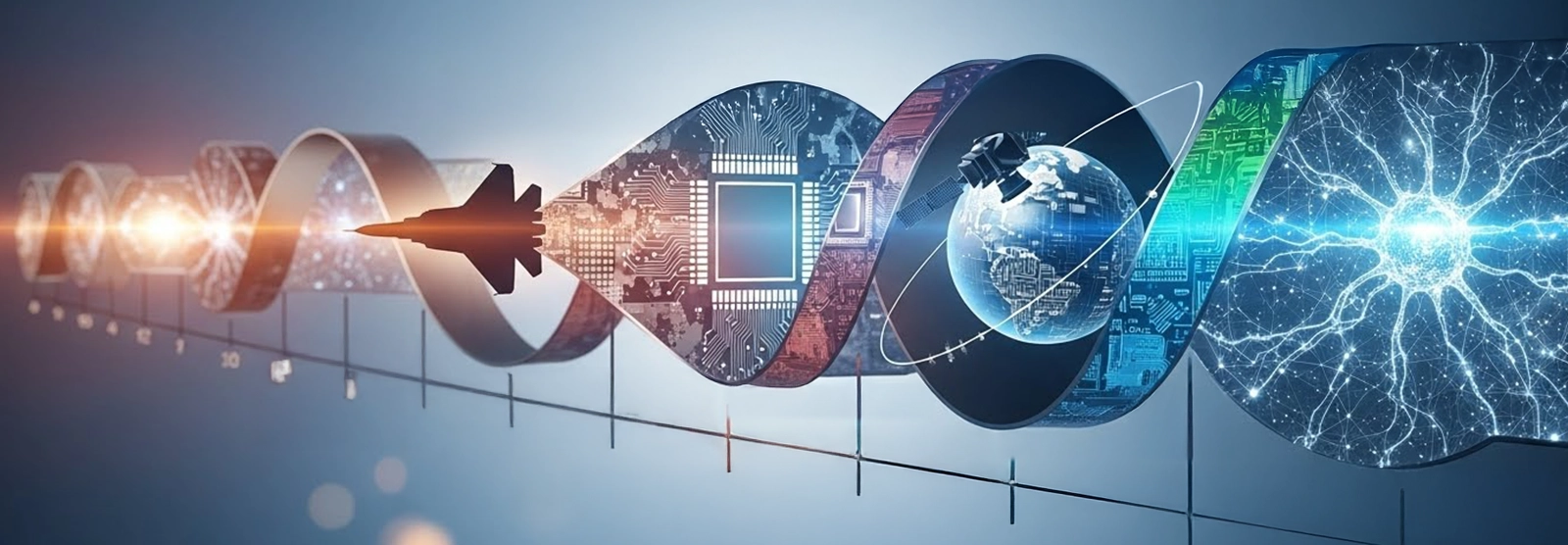

Delivering Multi-Platform, Multi-Mission, Cutting-Edge Technologies for Decades

From high-altitude reconnaissance and unmanned systems to extreme manned flight envelopes—our innovations enable missions where failure isn't an option.

From high-altitude reconnaissance and unmanned systems to extreme manned flight envelopes—our innovations enable missions where failure isn't an option.

Decades of combined experience in thin-film technologies, defense systems, and advanced manufacturing.

CEO

Mr. Nevolo brings over 25 years of proven expertise across technology, aviation, and energy sectors. His career spans from pioneering the world's first aerobatic helicopter team and achieving FAA Type Certification for aerobatic operations, to developing breakthrough wearable technology and advanced manufacturing capabilities for essential thin-film technologies. Mr. Nevolo led the comprehensive engineering analysis and certification team to achieve BO-105 airframe type certification through the FAA ACO/AIR, conducting rigorous analysis of aerodynamic forces and structural loads under aerobatic stress conditions, and managed the historic helicopter landing on Mt. Everest while navigating complex international logistics hurdles. His aviation credentials include Rotorcraft pilot certification with 5,000+ flight hours and successful management of experimental flight test programs for ex-military aircraft, ensuring full FAA compliance throughout specialized operations.

In the energy and technology sectors, Mr. Nevolo has co-developed proprietary intellectual property for solid-state hydrogen extraction and ultra-lightweight fuel cell power systems intended for use in UAS platforms, achieving an industry-leading energy density of 840Wh/kg—representing a 3X improvement over conventional lithium battery technology. His work as program manager for DEVCOM ARL's Dismounted Soldier wearable power integration program resulted in a 77% weight reduction while maintaining equivalent power output for critical systems. Combining deep technical expertise in advanced materials science, additive manufacturing, and power systems integration with strategic business acumen, Mr. Nevolo has successfully productized military technologies for consumer markets while establishing industry-leading performance standards for extreme environment applications. His comprehensive experience in startup fundraising, cross-platform product development, and regulatory certification positions him uniquely to deliver innovative solutions that meet the demanding requirements of both technology and defense markets.

Principal Architect, Printed Electronics Systems

Mr. LeFebvre is an internationally recognized senior executive with visionary leadership and innovative expertise spanning business management, engineering, additive manufacturing, and team development. With a proven track record across advanced technology sectors—including medical devices, defense systems, and Printed Electronics manufacturing encompassing High Energy RF mitigation and manipulation, antenna design, smart surfaces, medical wearables, on-body thin film sensors/diagnostics, and covert devices for high-security applications—he has driven operational excellence at industry giants including Medtronic, GE Medical, Lockheed Martin, and Raytheon. His tenure leading groundbreaking R&D initiatives at Primary Image, Inc. resulted in significant patents, industry awards, and transformative advancements in Printed Electronics technologies. Renowned for mentoring high-performance teams and fostering innovation-driven cultures, Mr. LeFebvre consistently delivers measurable results and creates lasting organizational impact across complex technical programs.

His technical contributions have culminated in an extensive patent portfolio and prestigious industry recognition, including multiple Global Industry Awards for pioneering advancements in thin-film electronics circuit architecture and high-resolution human-machine interface (HMI) technologies integrated within in-mold decoration (IMD) systems. Mr. LeFebvre's expertise in transitioning cutting-edge research from laboratory concepts to scalable manufacturing solutions has established him as a key innovator in the development of next-generation printed electronics and smart material systems.

Precision layer-by-layer additive manufacturing for photonics, thermal management, RF electromagnetics, advanced sensors, and flexible hybrid electronics.

Electromagnetic spectrum operations, metasurfaces, transparent antennas, and distributed electronic warfare capabilities.

Roll-to-roll and screen-printing production of circuits, sensors, antennas, and power systems on flexible substrates.

Decades of proven applications on manned platforms now adapted for unmanned systems and attritable autonomous operations.

Domestic manufacturing infrastructure ensuring ITAR compliance and eliminating foreign dependencies for mission-critical systems.

Physics-based authentication systems using physically unclonable optical structures for unhackable verification.

The United States cannot afford strategic dependencies on foreign manufacturing for defense-critical electronics, authentication systems, and advanced materials. Foreign supply chains don't just delay critical systems—they compromise them. Counterfeit components infiltrate weapon systems. Adversaries map vulnerabilities through the parts we source overseas. Electronics arrive obsolete, backdoored, or don't arrive at all. While we wait on foreign manufacturers, adversaries advance electromagnetic warfare, autonomous swarms, and supply chain attacks designed to cripple our response before conflict begins.

Standard Industries delivers sovereign, rapid-response production of enabling technologies that adversaries cannot compromise, replicate, or interdict. Every capability we develop—from conformal antennas to quantum-grade security tags—is designed and manufactured domestically using U.S.-developed materials and patent-protected processes. Our thin-film manufacturing and field-deployable production systems eliminate foreign dependencies, building mission-critical electronics on American soil at the speed of conflict.

This isn't just advanced technology; it's national security architecture built layer by layer.