Reinforcing America's Supply Chain for Critical Capabilities

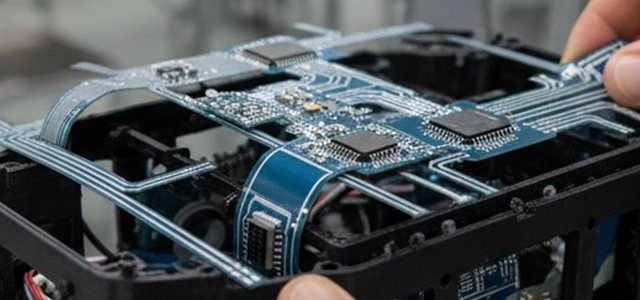

The United States cannot afford strategic dependencies on foreign manufacturing for defense-critical electronics, authentication systems, and advanced materials.

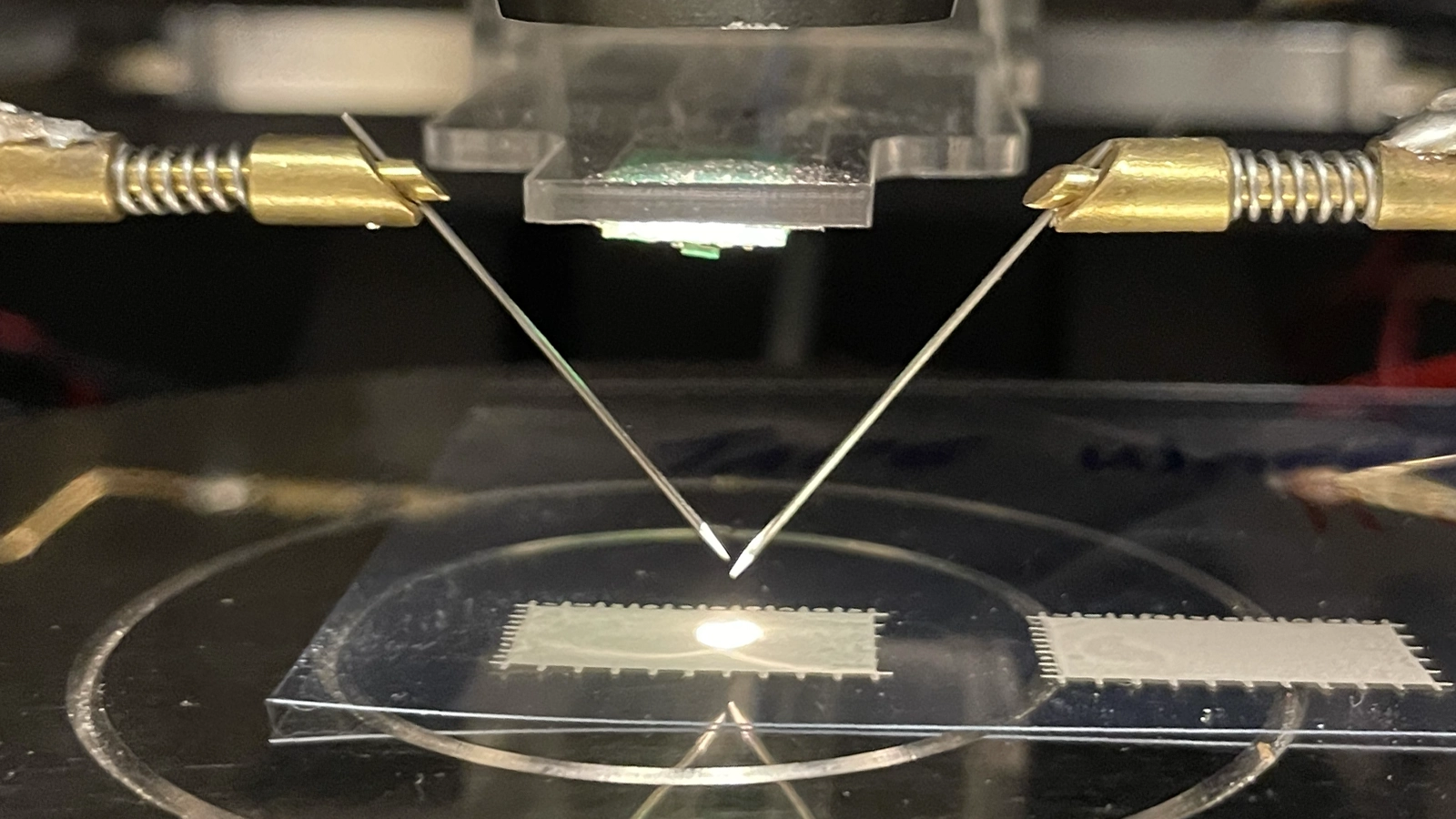

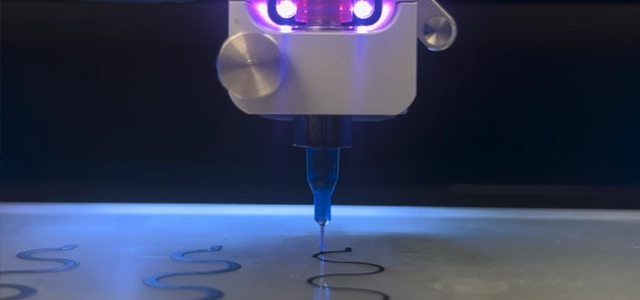

Every capability we develop—from transparent antennas to quantum-grade security tags—is designed and manufactured domestically using U.S.-developed materials and patent-protected processes.

This isn't just advanced technology; it's national security architecture built layer by layer.